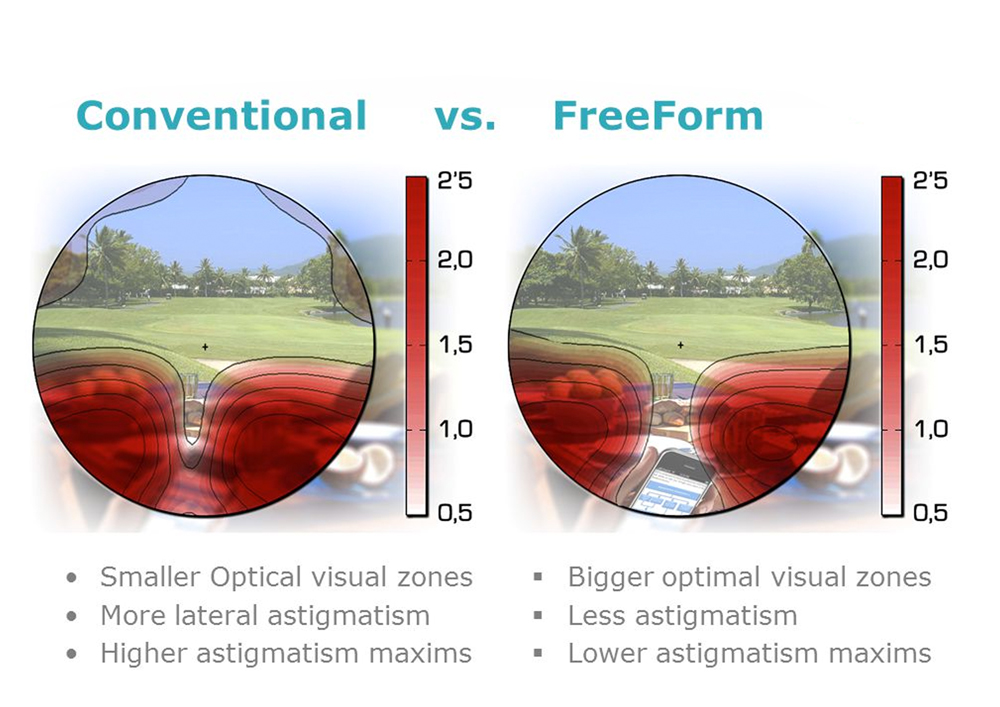

ROL has invested in Free-form technology which is the most advanced optical lens manufacturing processing. The technology reduces higher-order aberrations such as aspherical aberration that can occur in ophthalmic lenses processed using conventional or traditional manufacturing equipment. Free form technology uses computer-aided design and surfacing to create high-level, customized lenses . The technology allows us to process unique prescriptions and the cut edge and fit capabilities allow us to process any type of lens.

The High-definition free-form ophthalmic lenses are fabricated utilizing software controlled surfacing equipment that produces lenses that are customized to each wearer’s eyeglass prescription. Free-form lens technology can surface ophthalmic lenses in prescribed power increments of 0.01 dioptre, compared to ophthalmic lenses processed with traditional lens manufacturing equipment which surfaces lenses in 0.25 dioptre increments.

Traditionally traditional surfaced lenses are 0.01 decimal places as compared to digital surfaced lens which are now 0.06 decimal places. This means digital lenses have the following benefits:

- precision

- high definition

- best vision corridors

- high quality lens

- tailor made to all types of visual demands